What Are the Main Components of a PV System? Here's Everything You Need to Know!

With global efforts to achieve carbon neutrality and build a sustainable future, solar power is becoming one of the most accessible and cost-effective renewable energy solutions. Whether it’s a residential rooftop installation, a commercial distributed system, or a large-scale utility plant, understanding the core structure and components of a solar photovoltaic (PV) system is essential.

So, what exactly makes up a PV system? What roles do different components play? And how can you choose the right setup for your needs? This article breaks down the key parts of a solar system and offers insights to help you get started in the world of solar energy.

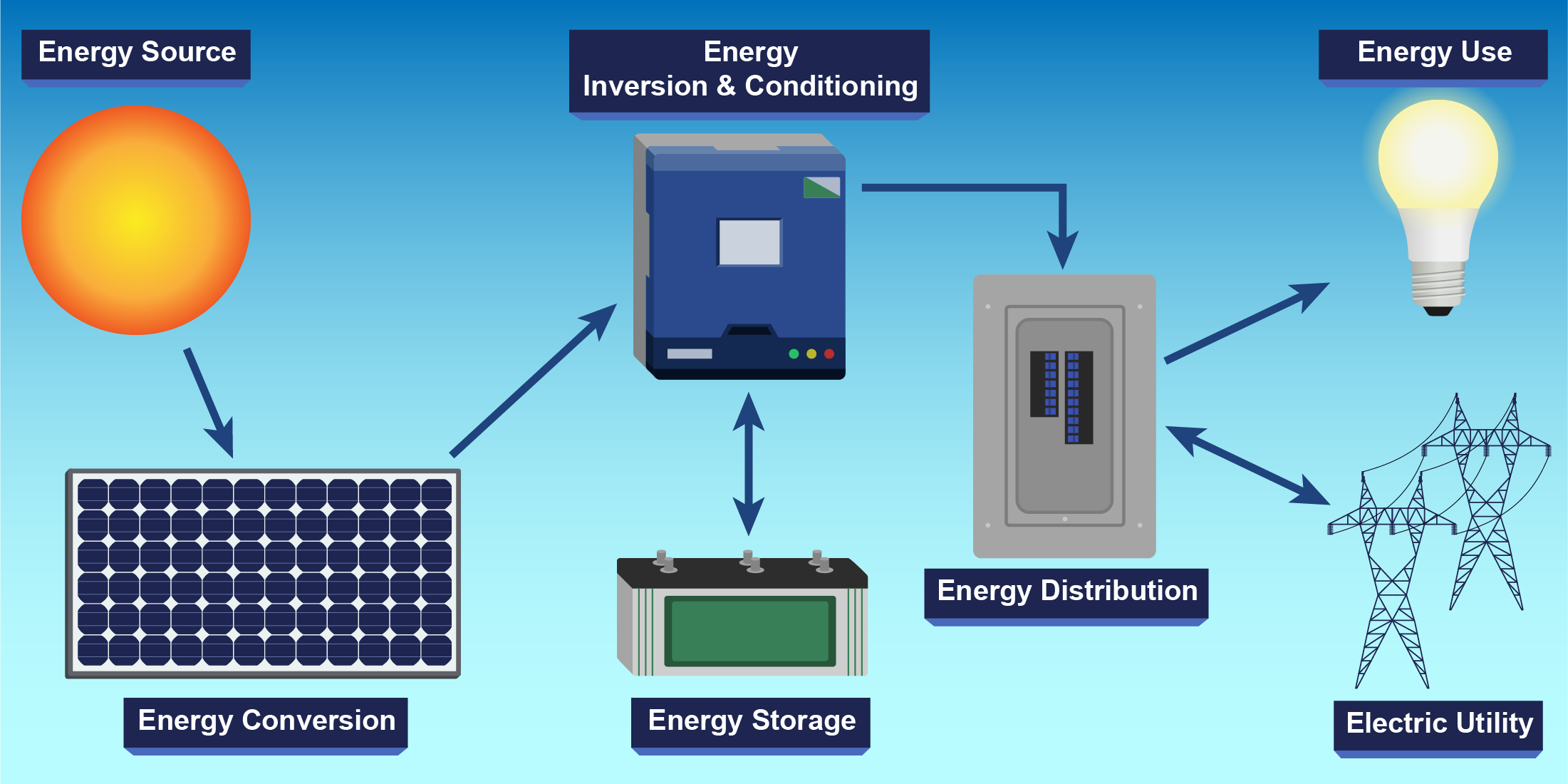

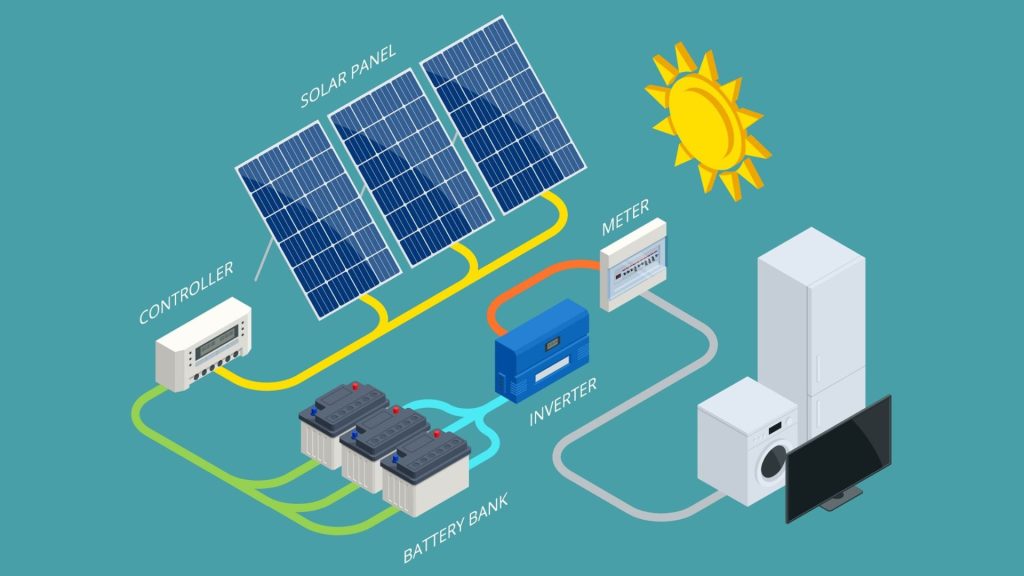

A complete solar PV system typically includes the following major components:

These are the heart of the system, responsible for converting sunlight into direct current (DC) electricity. Panels are made of multiple solar cells connected in series and/or parallel to achieve the desired voltage and power output.

This unit consolidates the outputs from multiple panel strings into a single DC output and provides protection against overcurrent through fuses or breakers. It's an essential safety and wiring component.

The cabinet handles secondary power distribution and protection. It connects the inverter to the grid or energy storage system, acting as a key control and transition point in the power flow.

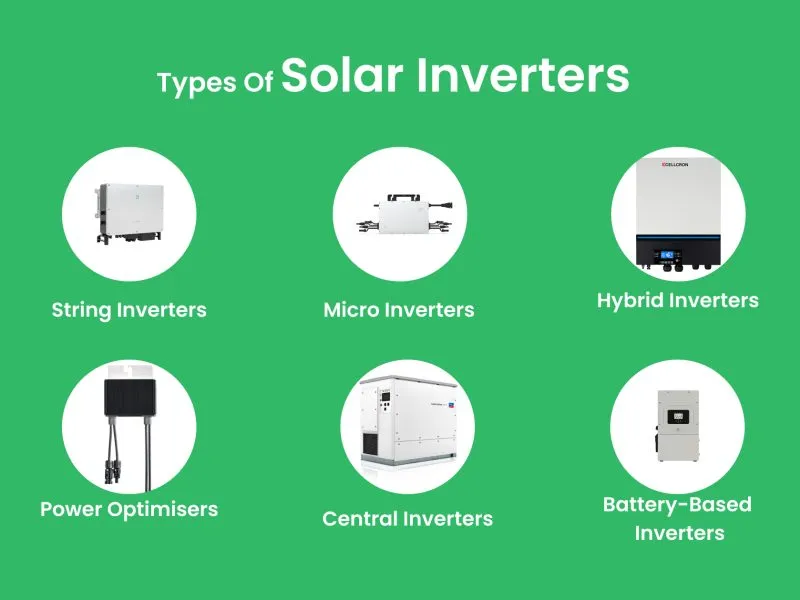

This is the system’s "brain," converting DC electricity from the solar panels into alternating current (AC) electricity used by household appliances or the grid. It also performs Maximum Power Point Tracking (MPPT), grid synchronization, and safety protections.

Used in utility-scale plants to step up the voltage for efficient transmission to the grid. It ensures the solar-generated power can be delivered over long distances with minimal loss.

A solar panel consists of dozens (sometimes hundreds) of solar cells packaged and encapsulated together. Since individual cells generate small amounts of electricity, they are grouped into panels to meet real-world power requirements.

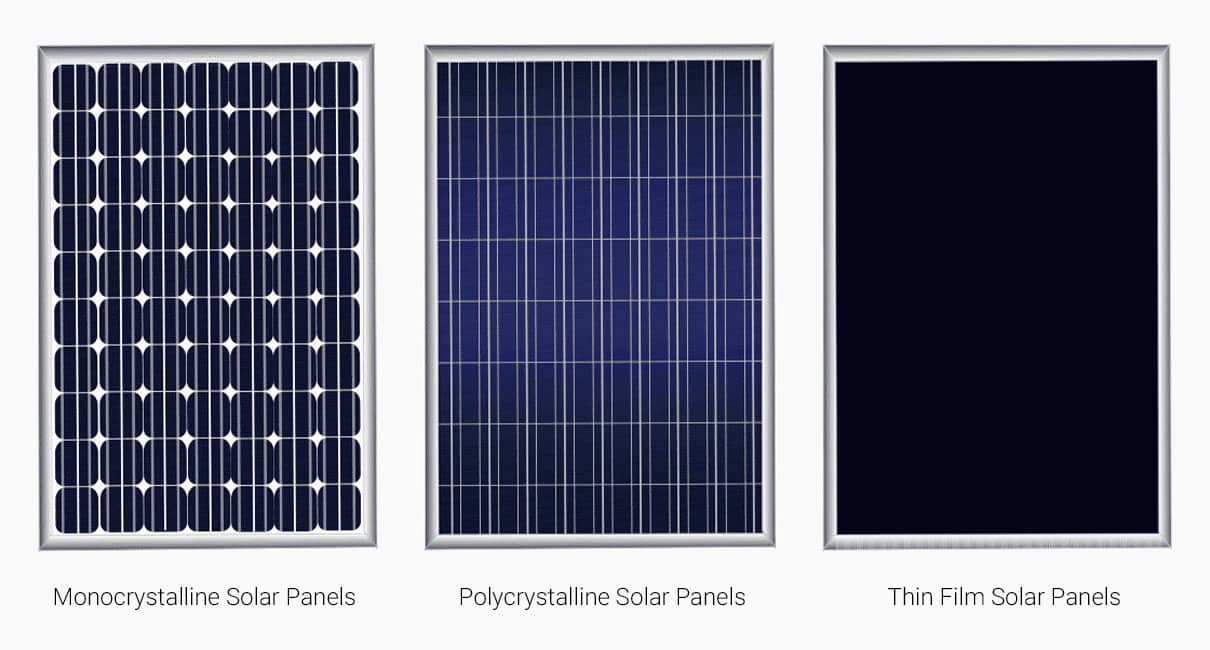

| Type | Efficiency | Appearance | Pros | Cons |

|---|---|---|---|---|

| Monocrystalline | 21–24% | Black or dark blue | High efficiency, long lifespan | Higher cost |

| Polycrystalline | 16–18% | Light blue, grainy texture | Cost-effective, mature technology | Lower efficiency |

| Heterojunction (HJT) | Up to 25% | Similar to mono | High efficiency, great low-temp performance | Expensive, not widely adopted yet |

| Thin Film (Perovskite/CIGS) | 15–22% (theoretical) | Flexible or semi-transparent | Lightweight, low-cost, good in low light | Shorter lifespan, lower stability, still under development |

🌟 Special Mention: Perovskite Panels

This new technology is generating a lot of buzz due to its high theoretical efficiency and low production cost. However, it still faces technical challenges such as shorter lifespan, potential toxicity, and limited commercial scalability.

Standard crystalline silicon panels are made of the following layers:

Tempered Glass: Protects the cells from weather and debris while allowing maximum sunlight penetration.

EVA Film: Encapsulates and binds the cells, providing durability and adhesion.

Solar Cells: The core energy-generating unit, converting light to electricity.

Backsheet (e.g. TPT or TPE): Provides insulation and environmental protection.

Aluminum Frame: Offers mechanical strength and helps with installation.

Junction Box & Sealant: Ensures safe external connections and waterproofing.

Aside from the inherent performance of the panels, several external factors can influence the overall efficiency of your solar system:

Caused by partial shading or damaged cells, leading to local overheating and potential panel damage. Can be prevented with proper panel layout and bypass diodes.

Occurs when high voltage differences cause power loss, especially in humid environments. Selecting PID-resistant panels and proper grounding can help mitigate this.

Tiny cracks in solar cells, often caused during shipping or installation, can reduce output. High-quality panels are usually EL-tested to detect and eliminate micro-cracks.

To maximize energy production, panel angles should match your local latitude (±10°). Simulation tools like PVsyst can optimize positioning based on sun exposure data.

As temperatures rise, panel output tends to drop. Panels with a lower temperature coefficient (e.g. -0.30%/°C) perform more reliably under hot conditions.

When selecting panels for your project, consider the following:

Budget vs Performance: Monocrystalline panels offer better efficiency, but polycrystalline can be more budget-friendly.

Roof Space: If space is limited, go for high-efficiency modules like N-type or HJT.

Climate Conditions: In areas with high humidity, temperature, or dust, choose panels with strong resistance to PID and corrosion.

Warranty & Brand Reputation: Look for panels with a solid 25-year performance warranty and a proven track record in quality control.

A well-designed PV system depends not only on panel quality but also on how each component integrates within the system. Choosing the right modules, inverter, and accessories ensures long-term performance and safety.

Address : Room 305, Tower B, Yinuo Business Center, intersection of West Second Ring Road and Hehuan Road, Bijiashan Street, Shushan District, Hefei city, Anhui Province

Please read on, stay posted, subscribe, and we welcome you to tell us what you think.

Links: Inverter Cables

Cowellxm

Copyright 2026 @ Anhui Solarasia Energy Technology Co.,Ltd .All Rights Reserved. Sitemap | Blog | XML | Privacy Policy

Network Supported

Network Supported